|

Model

|

HW-350/450

|

|

Dimension (L*W*H) mm

|

4430*1620*1710

|

|

Weight

(kg )

|

2300

|

|

Power supply

|

3P5W,380V /220 V , 50/60HZ 63A

|

|

Startup

power

|

26 kw

|

|

Operation power consumption

|

12kw

|

|

Control

system

|

Siemens PLC+Computer

|

|

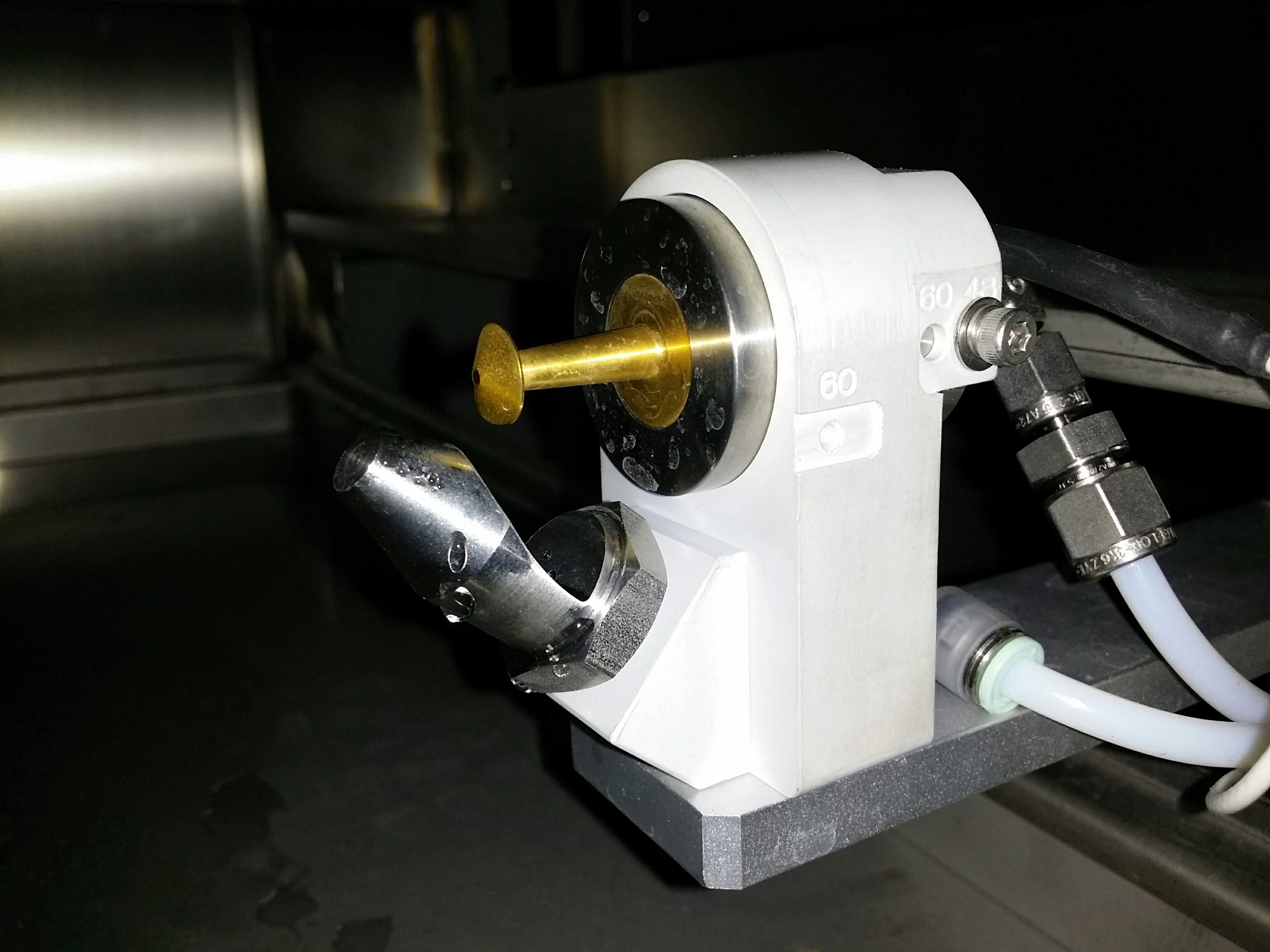

Spray

system

|

|

Transmission

method

|

Stepping motor

|

|

Sprayer nozzle

|

Japan ST-6

|

|

Spray

pressure

|

0.25MPa – 0.4 Mpa

|

|

FLUX flow arrange

|

10-100ml/min

|

|

FLUX

supply

|

Automatic

|

|

Exhaust air

|

Up exhaust

|

|

Exhaust

capacity

|

25M3/min

|

|

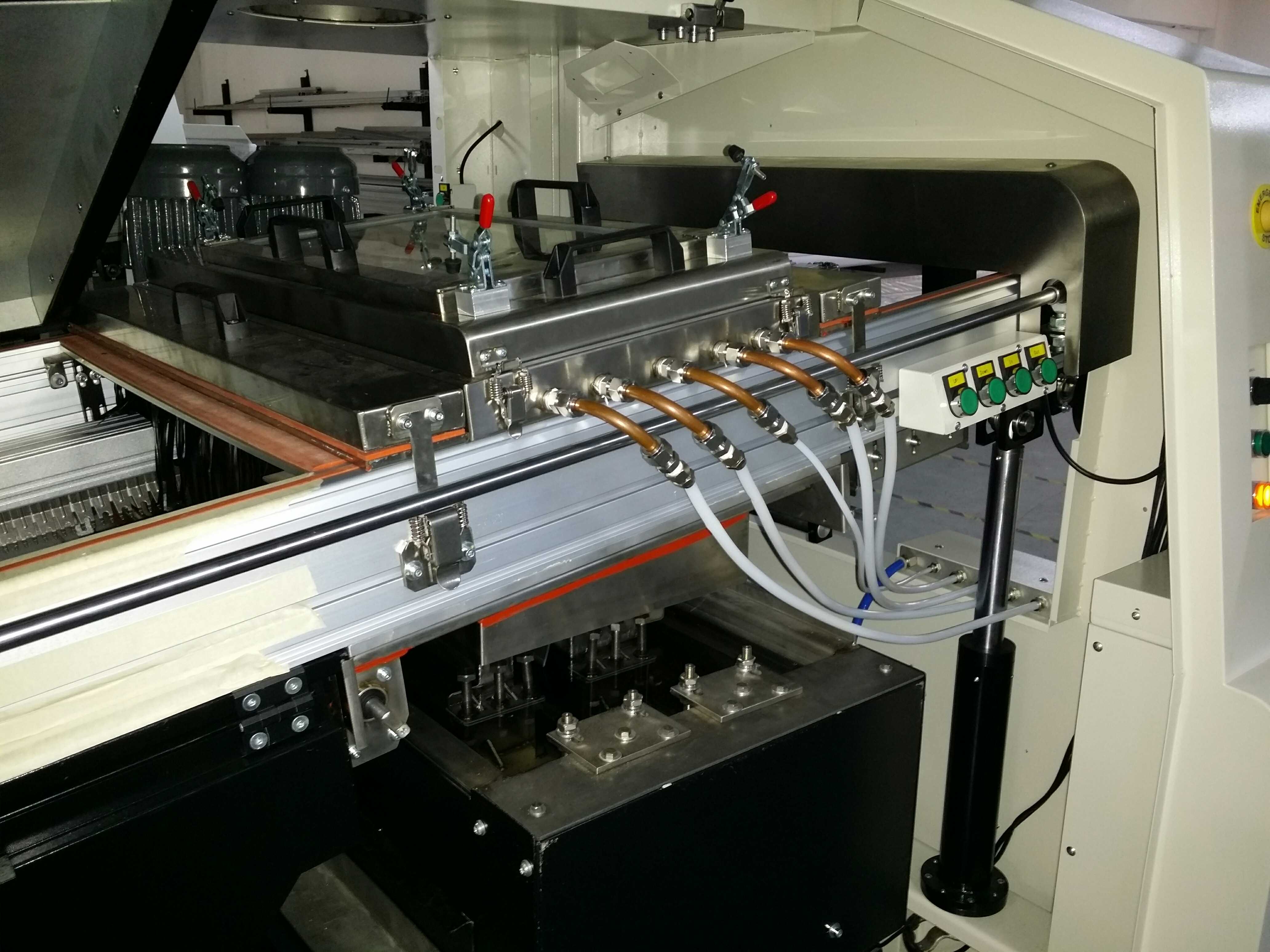

Preheating

system

|

|

Preheating

method

|

Hot air

|

|

Control mode

|

PID+SSR

|

|

Preheating

zones

|

Length :1800mm

Room temperature –250°C

|

|

Warmingup time

|

15 minutes ( setting 150°C )

|

|

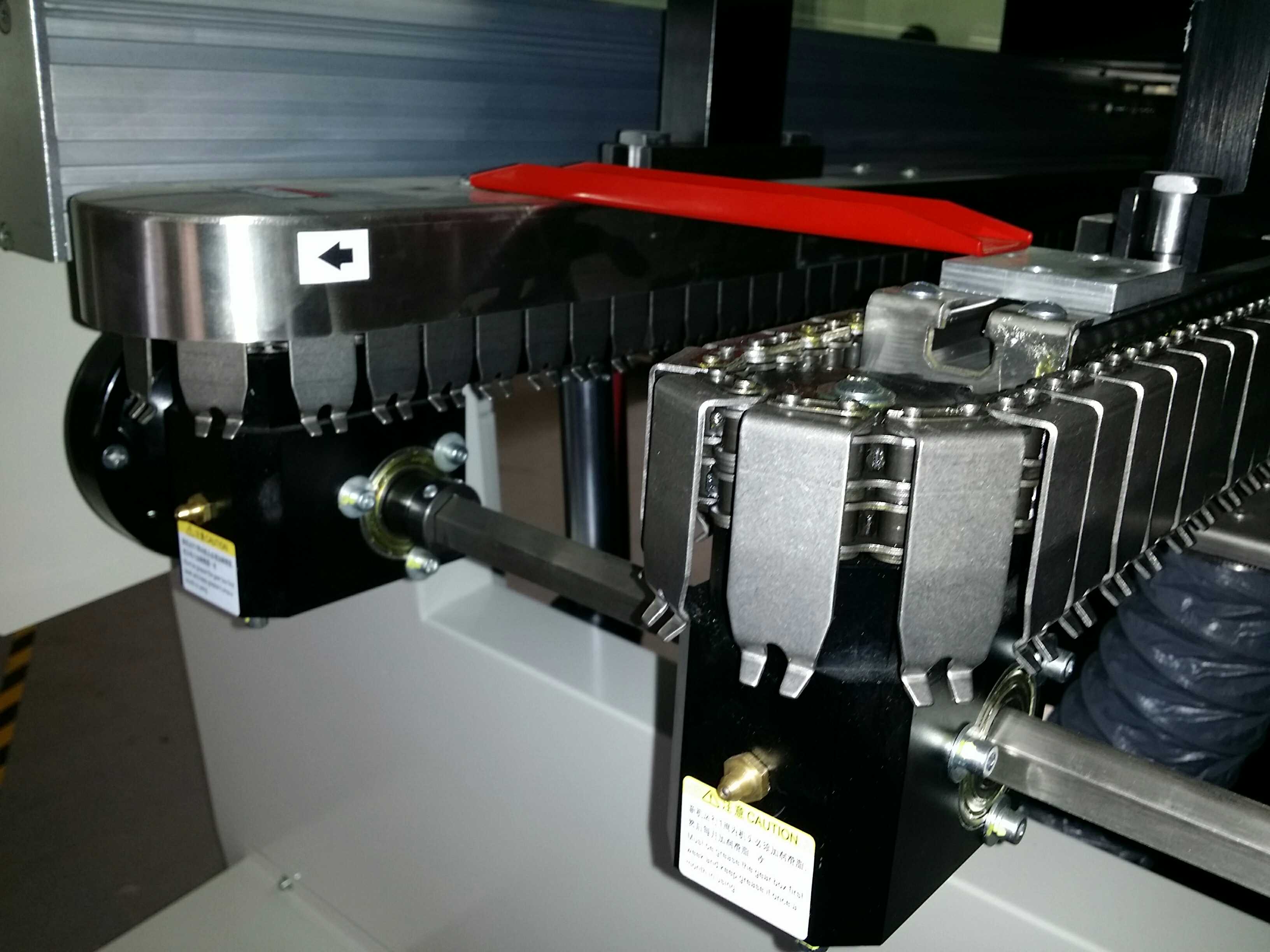

Conveyor

system

|

|

PCB Width (L*W) mm

|

Min : 80*60;Max:500*450

|

|

PCB

Conveyor direction

|

LàR/

RàL

(optional )

|

|

PCB Conveyor height (mm)

|

750+/- 20

|

|

Conveyor

speed (mm/ min )

|

0-2000

|

|

Available components height (mm)

|

Top :120mm ( 160mm Optional ) Down:

15 mm

|

|

Finger

|

Special Titanium Claw

|

|

Rail width control

|

Auto

|

|

Conveyor

angle

|

4°—7°

|

|

Soldering

system

|

|

Soldering

Pot style

|

Motor drive

|

|

Solder pot material

|

Titanium alloy

|

|

Wave

|

Duble wave

|

|

Wave height adjust

|

Digital control by PC

|

|

Heater

power

|

380AC 12KW

|

|

Solder pot capability

|

HW-450: Pb-Free 480kg

|

|

Solder

pot temperature

|

300°C

|

|

Solder pot warm-up time

|

Approx.180 min ( setting 250°C)

|

|

Temperature

control mode

|

PID+SSR

|

|

Cooling system

|

Forced air cooling

|

|

Others

|

Finger cleaning system; Return

Trip lifting( Standard )

|

|

Optional

|

Top IR pre-heating,Nitrogen

system, Center support

|